Defining a Pore Size and Sterile Filtering; 0.2 Micron vs. 0.22 Micron. What’s the difference?

If you were to spend a little time perusing Sterlitech’s selection of membrane disc filters, one thing we’re very proud of might just jump out at you: we have a lot of pore sizes. So many that you might wonder if it’s a little excessive that we carry both 0.2 and 0.22 micron pore sizes. After all, both are used to sterilize fluid passed through them. Can the tiny difference of 0.02 microns really change a filter’s performance characteristics that much?

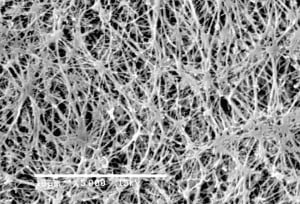

To answer that question, we must first take a look at one of the methods used to test a filter’s performance: the bubble point test1. Standard tests to verify a filter’s stated pore size usually entail a bubble point test. This test pushes air under pressure through a submerged membrane (either in water or alcohol) to the point where air bubbles first begin to come through the filter membrane2. The largest pore, or pores, in the membrane will bubble first, and the air pressure required to push the bubbles through these pores can be mathematically correlated to pore size. The irregular and tangled nature of the pores of most membrane filters makes it impossible to directly measure the size of an individual pore, so the bubble point test is used to determine the smallest particle that the filter can sieve out of a fluid.

In other words, the stated pore size of filter isn’t literally the size of the pores. It’s a rating of what can’t pass through them. Obviously, when sterilizing solutions, the object is to physically remove bacteria suspended in the solution. Before 0.2 and 0.22 micron filters became standard, it was thought that filters with an absolute rating of 0.45 micron were thought to be sufficient to strain out even the smallest bacteria. However, the discovery of Brevundimonas diminuta, showed that there were still bacteria capable of passing through a 0.45 micron filter in large quantities. After the discovery, researchers and labs competed to create the new filtration standard, arbitrarily defining their filters to be either 0.2 or 0.22 micron in pore size, roughly half the size of the old standard.

What that means is, for the purpose of sterilization, 0.2 micron and 0.22 micron filters are indistinguishable. Their performance is the same, only the difference being the designation of their pore size rating. The real measure of filter’s ability to sterilize fluid is passing the test described in ASTM F838-05, Standard Test Method for Determining Bacterial Retention of Membrane Filters Utilized for Liquid Filtration. Basically, if the filter can retain a minimum of 1 x 107 colony forming units (cfu) per cm2 of a challenge bacteria (usually B.diminuta5), then the filter is suitable to use for sterilization.

Even with the contraction of the standard pore size for sterilization, it turns out that simple size selection is not a sufficient method to fully contain all particles. Jornitz6 et al. showed adsorptive effects also change the manner in which different filter media capture different particles. Influences such as pH, pressure, bacterial load, and the liquid medium itself influence the size of bacteria. However, as long as the filters could capture the required number of challenge bacteria per square centimeter of membrane, then it is a valid sterilizing filter - whatever the stated pore size. Sterlitech Corporation is both a manufacturer and a reseller of different membrane filters, so you will see 0.2 micron and 0.22 micron in our filter offerings; but for sterile filtering, both are suitable based on the above information.

References:

- ASTM International. F838-05 Standard Test Method for Determining Bacterial Retention of Membrane Filters Utilized for Liquid Filtration (2005); https://www.astm.org/Standards/F838.htm.

- Cheryan, Munir. Ultrafiltration and Microfiltration Handbook. Boca Raton: CRC Press, Technology & Engineering. Jan 26, 1998. Print

- “Pharmaceutical Filtration: The Management of Organism Removal.” Parenteral Drug Association (PDA) Online Bookstore. Accessed online 28 May, 2014. https://store.pda.org/TableOfContents/Pharm_Filtration_Ch01.pdf

- Bowman, F.W., Calhoun, M.P., and White, M. “Microbiological Methods for Quality Control of Membrane Filters”, J. Pharm. Sci. 1967, 56: 222-225.

- Segers P, Vancanneyt M, Pot B et al. “Classification of Pseudomonas diminuta Leifson and Hugh 1954 and Pseudomonas Vesicularis Busing, Doll, and Freytag 1953 in Brevundimonas gen. nov. as Brevundimonas diminuta comb. nov. and Brevundimonas vesicularis comb. nov., respectively.” Int J Syst Bacteriol 1994; 44: 499–510.

- M.W. Jornitz, J.P. Agalloco, J.E. Akers, R.E. Madsen, and T.H. Meltzer “Filter integrity testing in liquid applications, revisited. Part II.” Pharmaceutical Technology, 2001, vol. 25, no. 11, pp. 24-35.

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/magefan_blog/b4.jpeg)